The rise of online retail has made last mile delivery an essential part of the entire supply chain. Last mile delivery deals with picking up products from the transportation hub and delivering them to the final customer. As omnichannel retail has been showing an upward trend, last mile delivery is also becoming equally important. But delivering a successful last mile experience comes at a cost and makes up almost 41% of the delivery cost.

What are the Major Cost Components in Last Mile Delivery?

1) Field Force

Last mile delivery can often get unpredictable. Some days, the deliveries could be fewer, whereas last mile deliveries could spike up during festive times or occasions. The company needs to ensure there is ample staff available to move and service last mile delivery requests on any given day. Every resource adds to the cost, so it is a great challenge for companies to utilize its field force to ensure both profitability and uninterrupted service.

2) Fleet Costs

3) Location Spread

4) Customer Experience

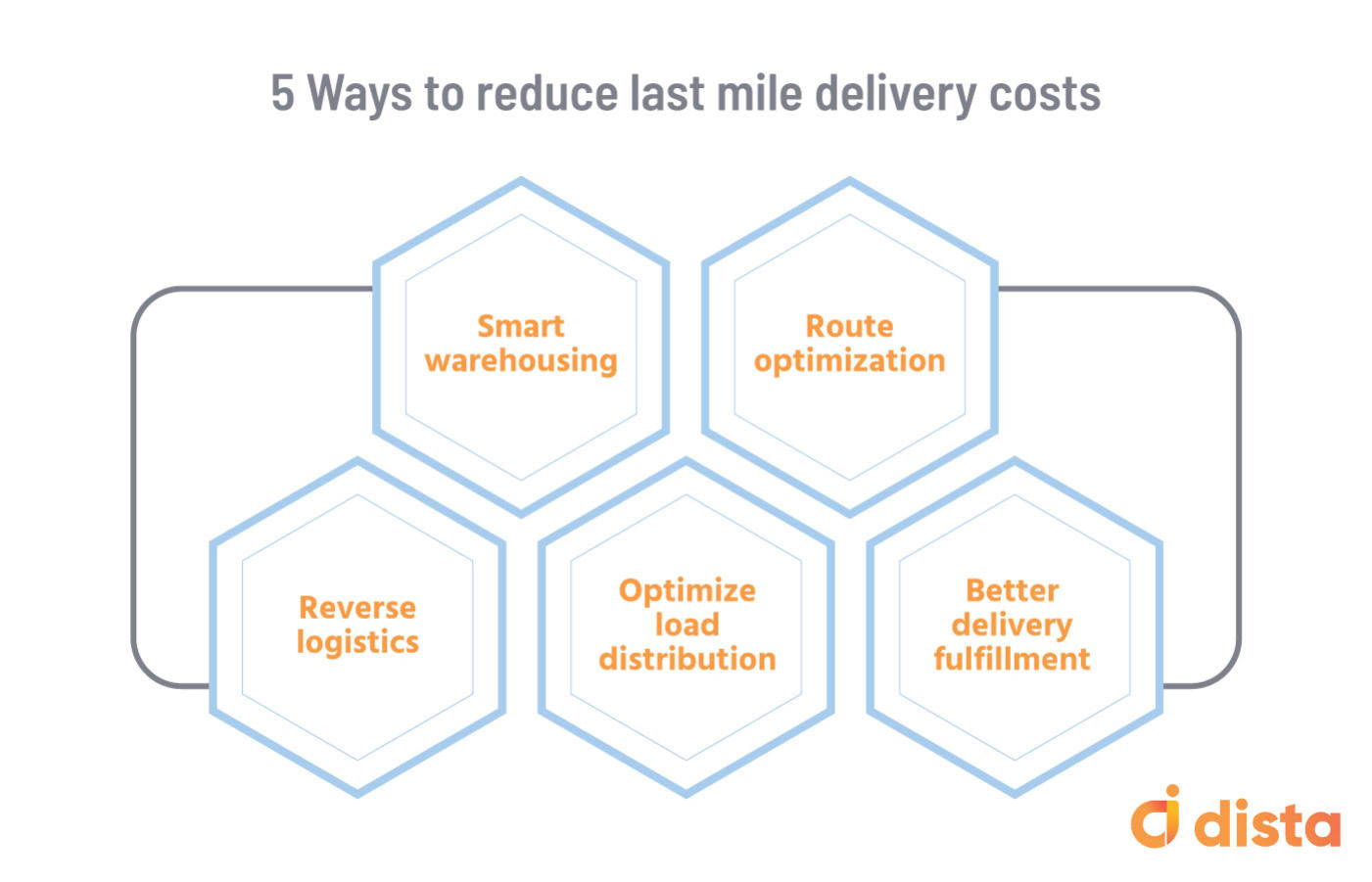

1) Smart Warehousing

Traditionally, warehouses used to mostly be situated on the outskirts of the actual delivery zone. The trend is now changing as hyperlocal and on-demand deliveries are rising in number. A good way to save on delivery costs is to reduce the distance a parcel has to cover. Having a warehouse smartly placed somewhere in the middle of the urban centers makes it easy to travel to the customer and meet the shorter delivery time window. Likewise, if the percentage of deliveries is more from extended suburbs, it would only make sense to have a warehouse placed somewhere around.

2) Route Optimization

Making your delivery routes efficient is another way to optimize the costs of your last mile delivery. In the absence of a route optimization software, your field force is left without much control at their disposal. Dynamic routing software enables your field force to choose the best beat-plan taking into account variable factors like traffic congestion, ETAs, and unforeseen weather conditions. Automated beat plans also help mitigate your expenditure on fuel costs and save time wasted on re-routing. Route optimization plays a big role in making your last mile efficient and cost-effective.

3) Reverse Logistics

Return pickups are often neglected. But did you know that reportedly for online shopping, the return probability is 30 percent as compared to 8-9 percent in brick-and-mortar stores? Studies also prove that more than 90 percent of buyers are ready for exchange or re-purchase if the return process is smooth, with almost 80 percent of shoppers preferring free return policies.

Reverse logistics contributes a big chunk to your last mile costs and is a tedious task. Here too, the whole last mile delivery process takes place, only in the reverse order. The delivery person picks up the package from the customer, checks for any issues and other documents (like bills or tags), returns it to the collection center, distributes to secondary outlets/ local retailers, resale/recycle before it finally reaches the new customer. Managing your reverse logistics well will ensure your last mile delivery costs are in check.

4) Optimize Load Distribution

5) Better Delivery Fulfillment

Leveraging multiple fulfillment locations enables speedy deliveries at a reduced cost. Placing warehouses in high demand density areas and dark stores for delivery pickups are becoming popular. This, along with flexible delivery options, can make the last mile cost-effective. Customers need to be given the flexibility to choose a delivery time and spot comfortable to them. This limits the number of failed and missed deliveries.

If the product is not needed on priority, a normal delivery speed can be offered along with a freebie like a cashback or coupon. Finally, automation can play a great role in subsidizing the last mile delivery costs. With automation, companies can dispatch better, track deliveries, as well as reach more accurate milestones. Investment in automation technology is surely a good bet to improve your last mile ROI in the long-term.