Supply Chain Network Optimization

Design High-performing Supply Chains

Redefine operational efficiency and improve cost-effectiveness with supply chain network optimization

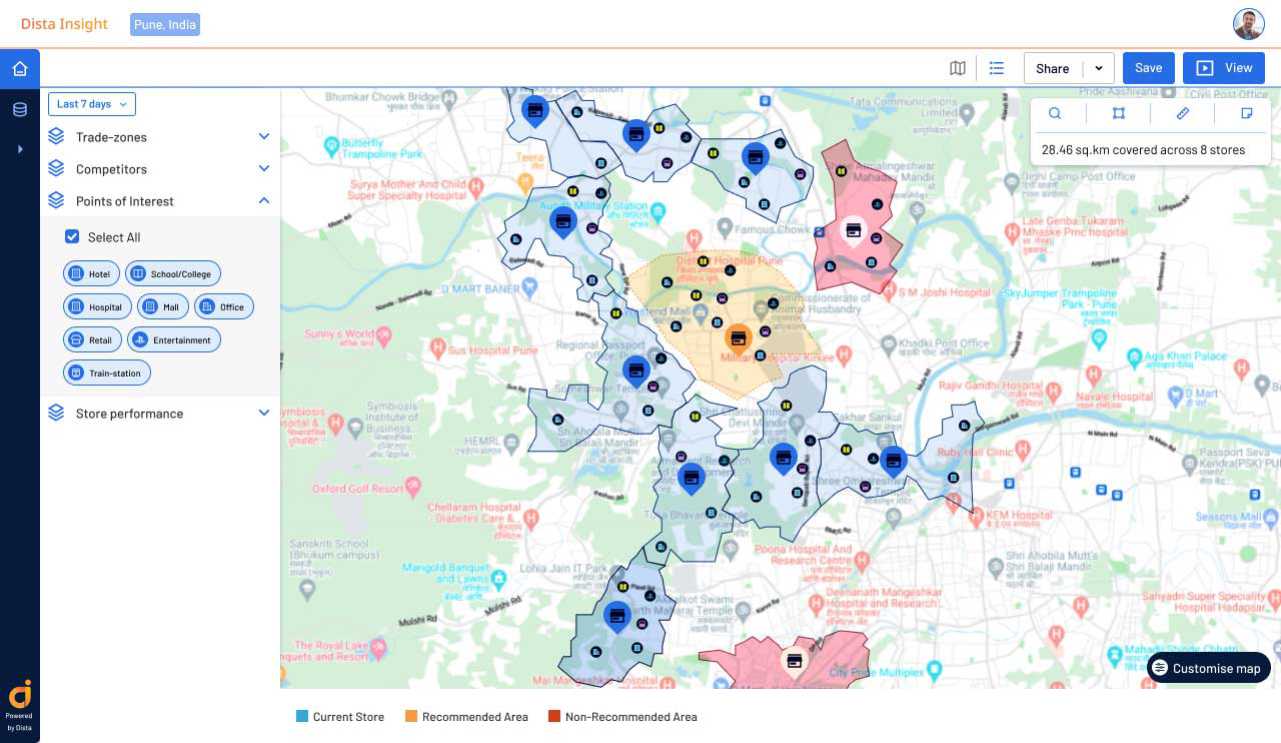

Intelligent Supply Chain Network Design

Design optimized supply chains using spatial analytics. Run simulations using 150+ constraints to identify the most optimal locations for setting up factories, warehouses, and distribution centers (DC) and reach customers faster.

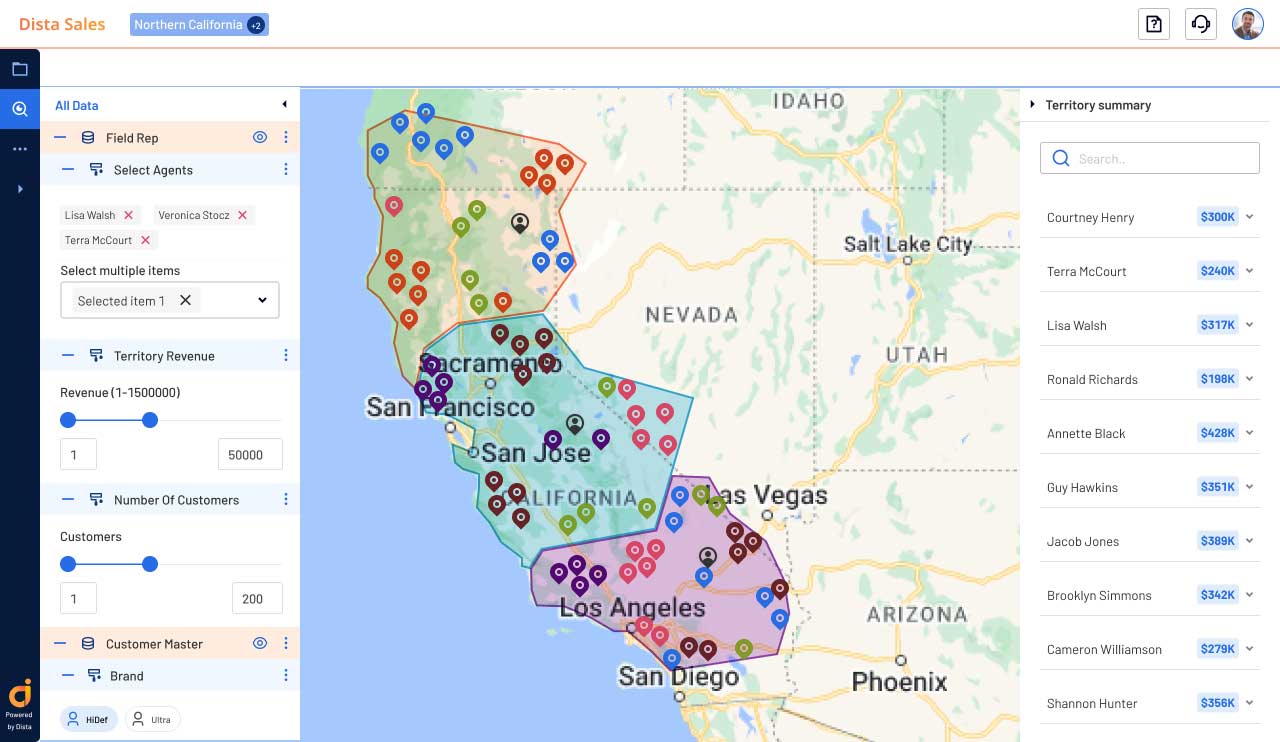

Optimize Territory Design

Create and visualize balanced territories to build a resilient supply chain. Run simulations using a hub and spoke model to identify the most suitable locations for setting up DCs and warehouses. Minimize logistics costs with effective utilization of vehicles and labor.

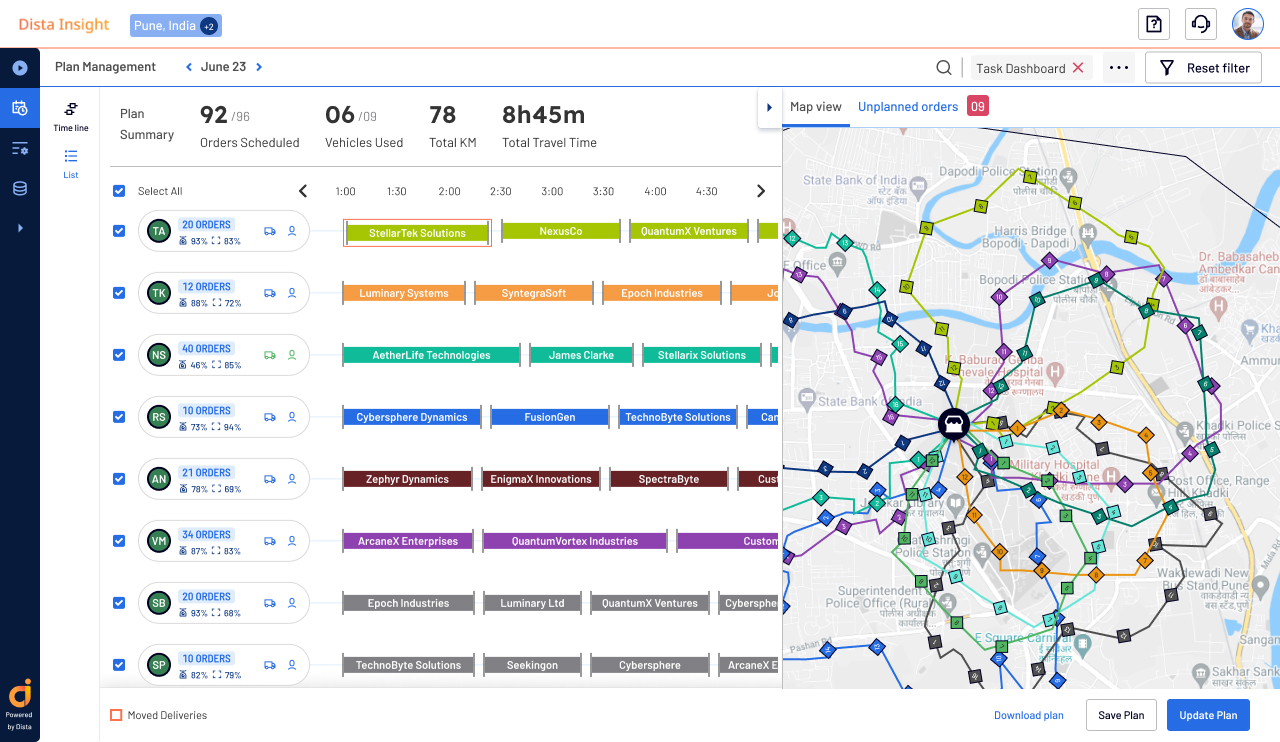

Elevate First to Last Mile Efficiency

Run multiple simulations using real estate trends, supply and demand in geographies, nature of the product, average order volume by location, number and type of vehicles, and labor cost. Use spatial patterns to schedule delivery sequences and design the most efficient route.

Demand Planning

Analyze the supply-demand ratio in your business coverage area. Set up warehouses and distribution centers by visualizing customer orders and the optimal route to market. Use spatial relationships with order trends to forecast demand. Evaluate the efficiency of each network simulation to maximize profitability.

Develop Strategic Route Models

Design strategic route models by overlaying spatial analysis on vehicles, warehouse/DC/factory location, customer volume, travel time, delivery schedules, area coverage, and more. Create multiple network models to improve the vehicle utilization rate. Reduce transportation and logistics costs with strategic route planning.

Master Network Optimization to Design Reliable Supply Chains

Fine Tune Network Design with Location Intelligence

FAQs

Browse our FAQs section to know more about our supply chain network optimization tool and how it can contribute to your success.

Still have questions ?

Spatial analytics leverages data to identify optimal locations for factories, warehouses, and distribution centers. This enables businesses to reach customers faster, optimize last-mile delivery, and minimize logistics costs.

Dista’s location intelligence-powered territory design creates balanced territories. It utilizes hub and spoke models to identify suitable locations for DCs and warehouses, minimizing logistics costs and ensuring efficient vehicle and labor utilization.

Dista’s AI/ML-powered platform analyzes location data to provide critical spatial insights, analyze the supply-demand ratio, visualize customer orders, and forecast demand. This allows you to strategically set up warehouses and DCs, maximizing profitability and operational efficiency.

Strategic route models overlay spatial analysis on various factors, such as vehicle routes, order volume, traffic patterns, delivery schedules, delivery sequences, and area coverage. By designing multiple network models, you can improve vehicle utilization rates and reduce transportation and logistics costs.

Dista supply chain network optimization software lets you run multiple simulations by leveraging 100+ business constraints. You can evaluate various factors such as geography, demand, and cost to identify the most optimal locations for setting up factories, warehouses, and distribution centers. This ensures efficient supply chain operations and enhanced customer service.